Silencer III

$435.00 - $640.00

Material:Large Porcelain Blades Time:24/11/2017

Material Application:TilePorcelainQuartz

Origin:China

Size:

14"16"18"Certifcated:CE / ISO / SGS

Custom Made:YES

Recommendation

Product Description

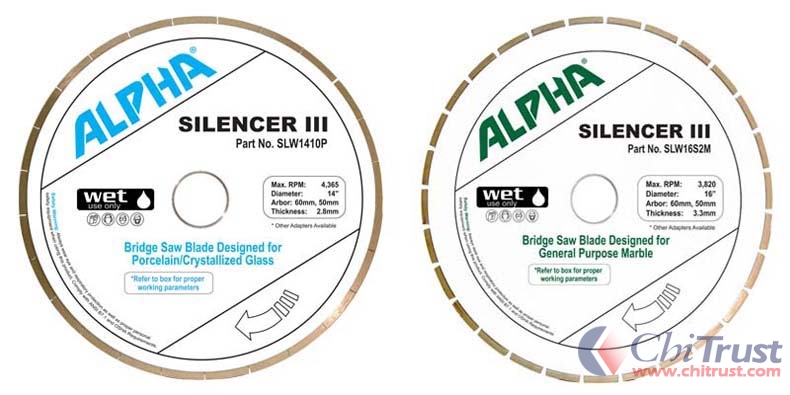

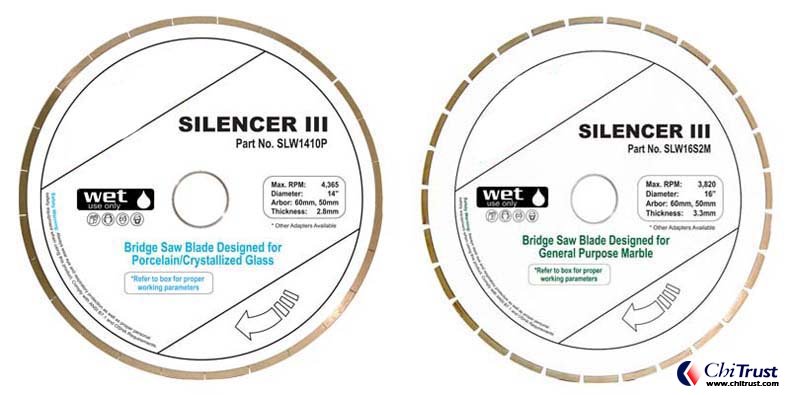

Silencer III for Quartzite

Chitrust is pleased to introduce the Silencer III for Quartzite. This high-quality blade for bridge or table saws is designed specifically for Quartzsite, a very hard stone that is often difficult to cut. Typically stone fabricators use general purpose blades for granite and quartz surface applications that may cut well for most popular softer materials; however, when the job calls for quartzite and harder granites classified as class 5 materials, general purpose blades will have difficulties cutting the materials and eventually stop cutting. There are potentially two problems associated with these difficulties.

First is the choice of blade and cutting the parameters. Most of the general purpose blades are designed for a wide range of applications that usually consist of softer to medium hard materials. Since the matrix and diamond grits are selected for softer materials, they typically do not work well on materials that are very hard.

The blade may cut for a short time but then start sparking at the cutting edge, although there is a plenty of water present. If you continue cutting, diamond grits get rounded and the matrix gets glazed. As a consequence, the blade stops cutting and the materials get broken. The second issue is the cutting parameters even though the blade picked is the right blade for quartzite. Since quartzite and class 5 granites have a high content of quartz, the diamond grits must work very hard to cut them, which may require slower peripheral and traverse speeds. When the selection of the blade is right and the recommended cutting parameters are followed, the blade will perform well on the harder materials.

Silencer III produces excellent cuts at significantly reduced noise level. This blade also achieves the highest cost-performance in its class. The uniquely designed core is made of two hardened steel sheets with a thin copper sheet laminated between them. This special construction dissipates the usually high noise levels common to this application. The blade is equipped with a 60mm arbor and comes with a 50mm adapter. Additional adapters are available as well.

Granite Marble Stone Floor Tile for Flooring and Wall

Color: White, Black, Grey, Coffee, Yellow, Red, etc.

Common size of Granite & Marble tiles:

12" X 12" or 305 X 305mm

16" X 16" or 400 X 400mm

18" X 18" or 457 X 457mm

12" X 24" or 300 X 600mm

24" X 24" or 600 X 600mm

Thickness: 10mm, 12mm, 15mm, 18mm, 20mm, 30mm,etc.

Thickness Toleranc: +/- 1mm,or +/- 2mm,Polished 85 Degree Up.

Usage: Used For Tile, Granite Tile, Flooring Tile, Granite Slab, Marble Slab, Wall Cladding Tile, Momument, Countertop, Kitchentops, Steps, Kerbstone, Paving Stone...etc.

Finish: Polished, Honed, Flamed, Sandblasted, Rough Hammered, Bush Hammered, Mushroom, etc.

Edge Finish: Bevel, Straight, Bull-nose, Round Edge,etc.

Granite is one of the hardest and most durable of all flooring tiles. Granite tile is a perfect choice for hard surface applications where durability and low maintenance is important, such as tiles for kitchen countertops, high traffic floors and tile flooring for commercial applications.

As an elegant & high-end building material,is widely in many housing areas.we invite you to enjoy this visual feast and aunderstand marble interior flooring better.